Sharpening systems for the edge you need. Rely on the experts in edges for all of your sharpening needs. For quick edge touch-ups and restoring factory edges, Dexter gives you the solution. Each sharpening solution is designed to give you the edge you need quickly to excel in today’s demanding and fast paced food service industry.

For efficient performance always keep your Dexter-Russell knives sharp. Remember, a dull knife can be dangerous. Keep all knives in a rack or block to prevent direct contact with each other or other hard objects. Don’t toss them in a drawer or use to open cans, remove jar and bottle caps or cut string, cones, metal, or paper. Always use a cutting board or proper cutting surface when chopping, slicing, or mincing…never cut on metal, glass, or porcelain.

Kitchen knives demand constant inspection for efficient performance. A fine cutting edge made from the best steel and the finest manufacturing know-how will turn its edge if used on a hard surface.

Ordinary slicing of meat will dull a good edge. However, this doesn’t mean that the knife requires re-sharpening. A few light strokes on a butcher’s steel will reset the edge and restore the knife’s keenness. Eventually this keen edge wears off and the use of a steel will not restore it. The knife must then be reground.

Careful grinding with a quality hand or motor-driven grinding wheel may be employed. It is of extreme importance, when grinding, not to overheat the blade, as excessive heat will draw the temper, and the blade will no longer hold its edge. A wet grindstone is the best possible protection against overheating. A good lubricated stone can be used when steeling fails to bring the edge back. With proper instructions, a person can become quite skilled at sharpening knives.

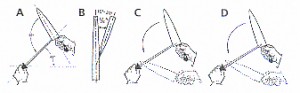

1. Grasp the sharpening steel firmly with your left hand (if right handed), placing the thumb securely behind the guard.

2. Place the heel of the blade against the steel at a 90° angle.

3. While keeping the cutting edge against the steel, raise the back of the blade approximately 1/4″ off the steel – or at 20°.

4. Try to maintain this angle and apply constant, moderate pressure as you draw the blade smoothly across and down the full length of the steel in one continuous motion until the blade tip completes the stroke by passing off the steel near the guard.

5. Repeat for the other side of the blade, only this time under the steel.

Loading... Please wait...

Loading... Please wait...